Ultimate Comparison: Top Tempering Machines for Chocolate - Find the Perfect Fit for Your Production Needs

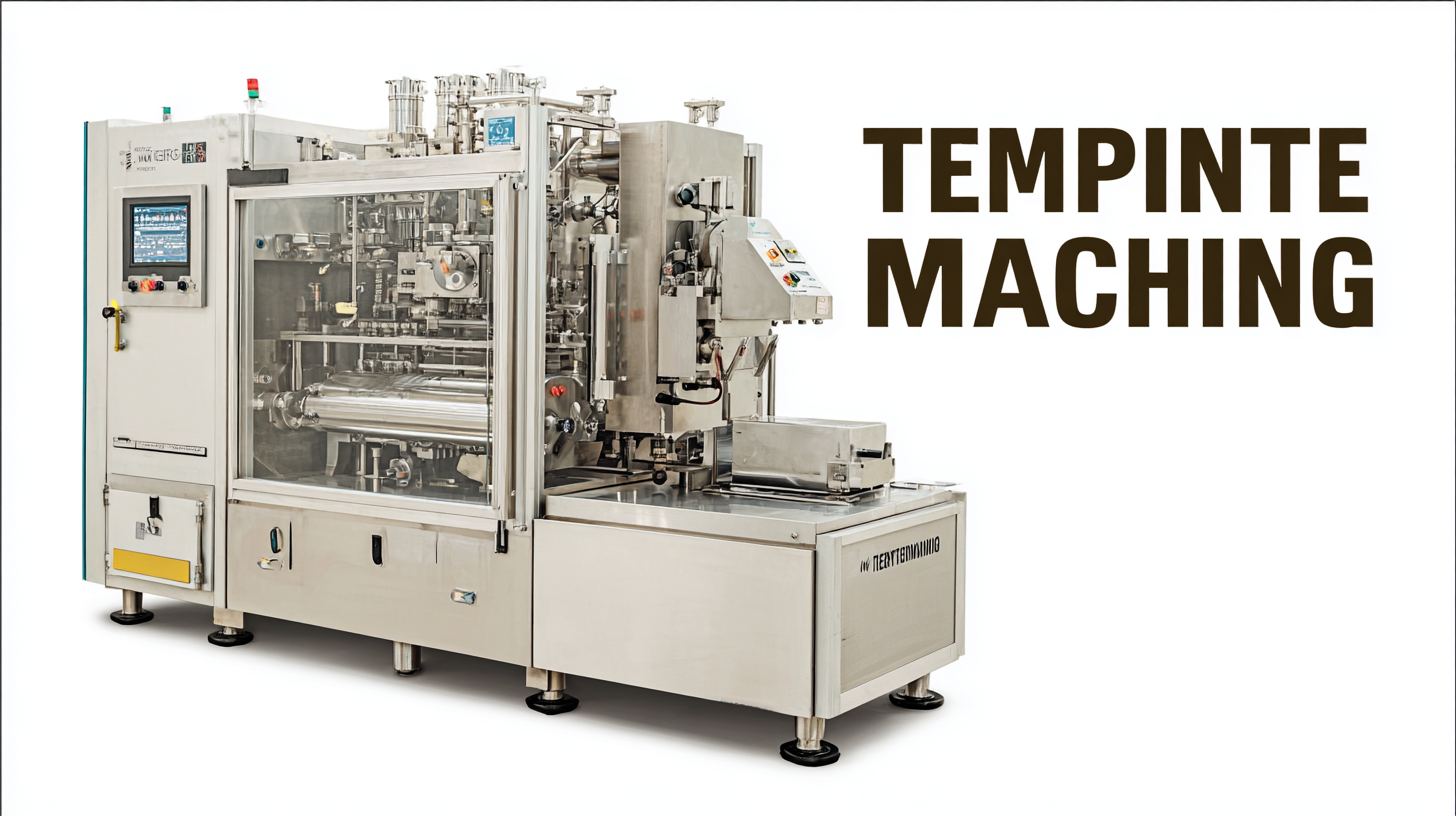

In the ever-evolving chocolate industry, ensuring the highest quality product is paramount, and this begins with the use of a reliable tempering machine for chocolate. According to a report by the International Cocoa Organization, the global chocolate market is expected to reach $230 billion by 2024, driven largely by the rising demand for premium and artisanal chocolates that require expert processing techniques. As manufacturers aim to refine their production processes, the significance of an efficient tempering machine cannot be overstated—it not only affects the texture and gloss of chocolate but also its overall flavor profile. With numerous options available, it's crucial for producers to identify machines that not only meet their specific production needs but also uphold the highest standards of quality, particularly those designed in China, which have recently emerged as global leaders in manufacturing excellence.

Key Features to Look for in Chocolate Tempering Machines

When choosing a chocolate tempering machine, several key features can significantly impact your production efficiency and product quality. One of the most important aspects to consider is temperature control. High-quality tempering machines offer precise temperature regulation, allowing you to maintain optimal conditions for chocolate tempering. This consistency not only enhances the texture and shine of the chocolate but also improves its shelf life.

Another feature to look for is capacity. Depending on your production needs, selecting a machine that can handle your desired quantity without compromising on quality is essential. Machines come in various sizes, so consider your output goals and the available space in your facility. Additionally, many modern machines have programmable settings that allow for customized tempering processes, which can be a game-changer for versatility in your recipes.

**Tips:** Always review the machine's energy efficiency ratings, as this can lead to savings in operational costs over time. Investing in a machine with user-friendly controls can simplify the tempering process, especially for smaller operations. Lastly, consider the ease of cleaning and maintenance, as these factors will ensure the longevity and reliability of your equipment.

Ultimate Comparison: Top Tempering Machines for Chocolate Production

Comparative Analysis of Manual vs. Automatic Tempering Machines

When it comes to chocolate production, the choice between manual and automatic tempering machines can significantly influence both product quality and operational efficiency.

Manual tempering machines typically cater to small-scale businesses or artisanal chocolatiers focusing on handcrafted products. According to a report from the Fine Chocolate Industry Association, about 70% of small chocolate producers prefer manual methods due to the meticulous control it offers in the tempering process, which is crucial for achieving the desired sheen and snap in chocolate. These machines often cost less initially and require minimal training, making them accessible for startups.

Manual tempering machines typically cater to small-scale businesses or artisanal chocolatiers focusing on handcrafted products. According to a report from the Fine Chocolate Industry Association, about 70% of small chocolate producers prefer manual methods due to the meticulous control it offers in the tempering process, which is crucial for achieving the desired sheen and snap in chocolate. These machines often cost less initially and require minimal training, making them accessible for startups.

On the other hand, automatic tempering machines are increasingly favored by larger operations looking to boost productivity and consistency. A study by the International Confectionery Association found that automated systems can increase production speed by up to 200% while minimizing human error, which is vital in a commercial environment. For instance, brands like Callebaut and Selmi report that their automatic units can precisely control temperature fluctuations, ensuring a uniform product while reducing waste. The transition to automation represents a significant investment, but the return in efficiency—often cited as a critical factor by 85% of manufacturers—can make it a worthwhile endeavor for those aiming to scale their production.

Top Brands to Consider for High-Quality Chocolate Tempering

When it comes to chocolate tempering, choosing the right machine is crucial for achieving high-quality results. Several brands have established themselves as leaders in the market, providing various options tailored to different production needs. One such brand is Chocovision, known for their innovative machines that combine advanced technology with user-friendly features. Their line of tempering machines helps chocolatiers achieve precise temperature control, ensuring a glossy finish and perfect snap.

Another notable name is Cacao Black, which offers a range of compact tempering machines ideal for small to medium-scale producers. Their products are designed with efficiency in mind, allowing for quick and consistent tempering that is essential for maintaining the chocolate's quality. Moreover, their commitment to sustainability and eco-friendly practices makes them a popular choice among environmentally conscious chocolate makers.

Lastly, Selmi is a brand that stands out with its high-performance tempering machines suitable for both artisan chocolatiers and larger manufacturing facilities. Their machines come equipped with advanced features like automatic stirring and user-friendly interfaces, making them a reliable option for achieving the best results. Each of these brands caters to specific needs, helping chocolate professionals elevate their craft and production capabilities.

Cost vs. Performance: Finding the Best Value Tempering Machine

When investing in a chocolate tempering machine, the delicate balance between cost and performance is crucial. While some manufacturers might be tempted to opt for the cheapest option available, it's essential to understand that quality often comes at a price. A high-quality tempering machine not only ensures a superior finish for your chocolate but also minimizes waste and enhances production efficiency. This can lead to significant cost savings in the long run, making it a smarter investment for businesses looking to grow and scale.

Evaluating the best value temperature machines requires careful consideration of various factors beyond just the upfront costs. Performance indicators such as speed, consistency, energy consumption, and ease of use play a critical role in determining the overall value. Some machines may have higher initial costs but offer faster tempering times, reducing the overall manufacturing cycle. Additionally, machines with advanced technology may require less maintenance, further saving on operational costs. By focusing on both cost and performance, producers can find the perfect tempering machine that aligns with their production needs and financial goals.

Ultimate Comparison: Top Tempering Machines for Chocolate

| Model | Capacity (kg/h) | Temperature Range (°C) | Heating Method | Price ($) | Performance Rating |

|---|---|---|---|---|---|

| Model A | 25 | 20 - 50 | Induction | 3000 | 4.5/5 |

| Model B | 30 | 25 - 55 | Water | 3500 | 4.2/5 |

| Model C | 20 | 18 - 48 | Electric | 2500 | 4.0/5 |

| Model D | 35 | 15 - 50 | Induction | 4000 | 4.4/5 |

| Model E | 40 | 20 - 60 | Water | 4500 | 4.7/5 |

Maintaining Your Tempering Machine for Optimal Chocolate Quality

When it comes to maintaining your tempering machine for optimal chocolate quality, regular upkeep is essential. A well-maintained machine not only enhances the flavor and texture of chocolate but also prolongs the lifespan of your equipment. Routine cleaning, thorough inspections, and timely maintenance checks are critical. Ensuring that all parts are free from debris and residue will prevent contamination and ensure a smooth tempering process.

Tips: Clean your machine regularly to avoid buildup that can affect chocolate quality. Use food-safe cleaning agents and ensure that the machine is dismantled and cleaned properly between uses. Additionally, monitor temperature settings carefully, as precise temperature control is key to achieving that glossy finish in your chocolate. Small fluctuations can lead to issues in tempering, so investing in quality thermometers can make a significant difference.

Lastly, don’t overlook the importance of training your staff on proper machine usage. Ensuring that everyone involved in the production process understands the nuances of the tempering machine will lead to more consistent results and higher-quality chocolate. A well-informed team is crucial for spotting potential problems early and maintaining the machine's performance.