What is a Steering Cylinder and How Does It Work?

The Steering Cylinder plays a crucial role in vehicle maneuverability. This component translates the driver's input into precise steering actions. According to industry data, over 60% of modern vehicles rely on hydraulic steering systems, where the steering cylinder is essential for smooth operation.

While steering cylinders are vital, they are not without challenges. Regular maintenance is critical; failure to do so can lead to significant steering issues. For instance, a worn steering cylinder can cause uneven handling, negatively impacting safety. The industry reports that nearly 20% of steering failures stem from these components.

Understanding the workings of a steering cylinder enhances our grasp of vehicle dynamics. It combines engineering precision with user experience. As vehicles evolve, so do steering technologies. Yet, maintaining effectiveness remains a constant challenge for manufacturers and users alike.

Understanding the Basics of a Steering Cylinder

A steering cylinder is a crucial component in various vehicles. It helps direct the motion of the vehicle. Understanding this part can clarify its significance in steering mechanics.

The steering cylinder works using hydraulic pressure. When you turn the steering wheel, fluid moves within the cylinder. This fluid pushes a piston, which in turn moves the wheels. It’s a simple yet effective system. However, people often overlook its importance. If not maintained properly, the cylinder may leak. Checking for wear is essential. Some may ignore the signs of trouble until it’s too late.

Regular inspection of the steering cylinder can prevent larger issues. In some cases, drivers may find the steering becomes less responsive. This is a warning sign. Addressing it early can save time and prevent accidents. Everyone should take the responsibility of understanding their vehicle's components. The nuances of a steering cylinder deserve attention. Awareness leads to better vehicle performance.

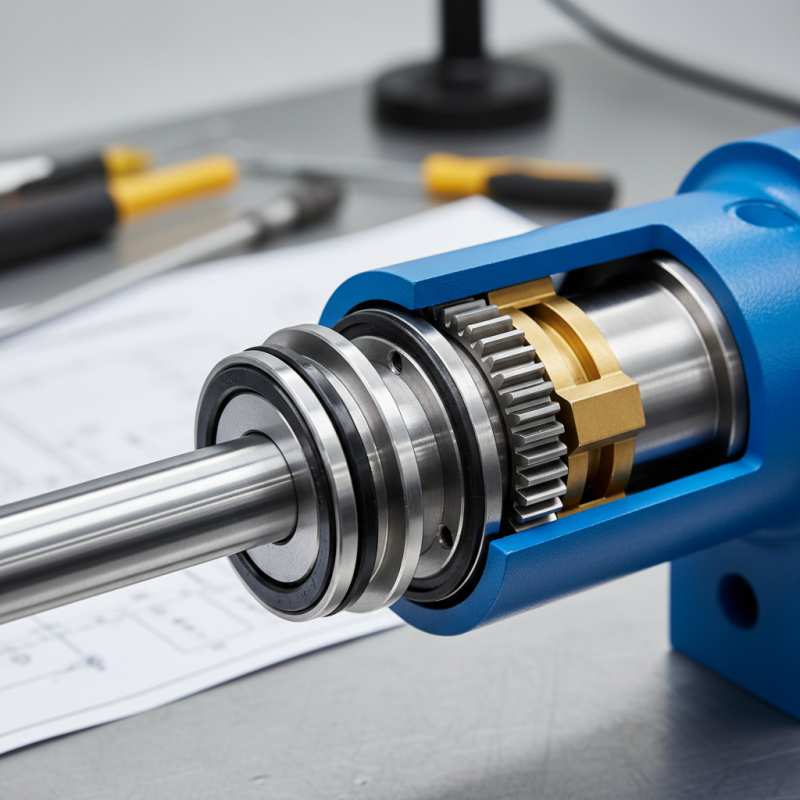

Components of a Steering Cylinder and Their Functions

A steering cylinder is crucial in the steering system of vehicles. It converts the driver's input into mechanical movement. Several components work together within this cylinder to ensure precise control.

The main part of a steering cylinder is the piston. It moves within a cylinder bore. When fluid pressure is applied, the piston shifts. This motion provides the necessary force to turn the vehicle's wheels. Guides keep the piston aligned, enhancing stability. The end covers seal the cylinder, preventing leaks and maintaining pressure. A rod attached to the piston connects to the vehicle's steering mechanism.

Hydraulic fluid circulates through ports, ensuring smooth operation. Sometimes, the seals wear out, leading to fluid leaks. This can cause steering issues. Regular maintenance is essential to avoid complications. Moreover, if the alignment is off, it might affect the steering response. Taking care of the steering cylinder ensures safety and improves vehicle performance.

What is a Steering Cylinder and How Does It Work? - Components of a Steering Cylinder and Their Functions

| Component | Function | Material | Typical Size (mm) |

|---|---|---|---|

| Cylinder Housing | Holds hydraulic fluid and provides structure | Steel or Aluminum | 150-300 |

| Piston | Converts hydraulic pressure into mechanical force | Steel | 50-100 |

| Seals | Prevents hydraulic fluid leakage | Rubber or Polyurethane | Varies by application |

| Rod | Transmits force from the piston to the steering linkage | Steel | 20-40 |

| End Fittings | Connects cylinder to the steering mechanism | Steel or Aluminum | Varies by application |

The Working Principle of a Steering Cylinder

A steering cylinder plays a crucial role in the steering system of vehicles. It is essential for controlling the direction of a vehicle effectively. When a driver turns the steering wheel, hydraulic fluid is directed into the steering cylinder. This action creates pressure, allowing the cylinder to move and assist in turning the vehicle's wheels.

The working principle of a steering cylinder relies on hydraulic fluid dynamics. As the fluid moves, it pushes a piston inside the cylinder. This piston action translates the driver's inputs into physical movement. It can offer a strong response. However, if any part of this system fails, steering can become unresponsive.

Components must be maintained properly. Worn seals can lead to leaks. Drivers might notice changes in steering ease or precision. Keeping hydraulic fluid at proper levels is vital. Regular checks and maintenance can prevent significant issues. Attention to detail is important.

Applications of Steering Cylinders in Modern Vehicles

Steering cylinders are crucial components in modern vehicles. They play a vital role in steering systems, helping drivers maintain control. These cylinders assist in the movement of the steering wheel, translating the driver’s input into real-time directional changes.

In contemporary vehicles, steering cylinders are commonly found in hydraulic systems. A report from the Society of Automotive Engineers indicates that hydraulic steering systems account for approximately 65% of the market share in automotive steering technologies. This popularity stems from their ability to provide precise handling and reduced driver effort, especially in larger vehicles. However, these systems can experience leaks or malfunctions, which may lead to safety concerns.

Electric steering systems are emerging as a popular alternative. These systems offer greater fuel efficiency and less maintenance, but they often lack the tactile feedback that many drivers prefer. According to a recent study by Frost & Sullivan, electric steering systems are expected to grow by 8% annually, potentially overtaking traditional systems in the coming years. Yet, some users report feeling a disconnect between their steering actions and vehicle response, raising questions about usability in certain driving conditions.

Steering Cylinder Applications in Modern Vehicles

Maintenance Tips for Steering Cylinders

Steering cylinders play a crucial role in vehicle and machinery control. Regular maintenance is vital for their longevity. Checking the hydraulic fluid levels is a simple yet effective step. Low fluid can lead to poor performance. Inspect the seals and hoses for any signs of wear or leaks. Even small leaks can lead to bigger problems.

Cleaning the cylinder regularly helps prevent dirt and debris buildup. Use a soft cloth to wipe any dust or grime. Dirt can cause friction and wear over time. Regularly test the steering function. Any unusual noises or resistance should not be ignored. You might need to recalibrate or even replace the cylinder if issues persist.

Consider keeping a maintenance log. Documenting your checks helps track your cylinder's health. Review this log periodically to spot patterns. Understanding past issues can prevent future problems. Small, consistent efforts can greatly enhance the efficiency of your steering cylinder. Remember, neglect can lead to costly repairs.