Unlocking the Secrets to Perfect Chocolate with a Tempering Machine

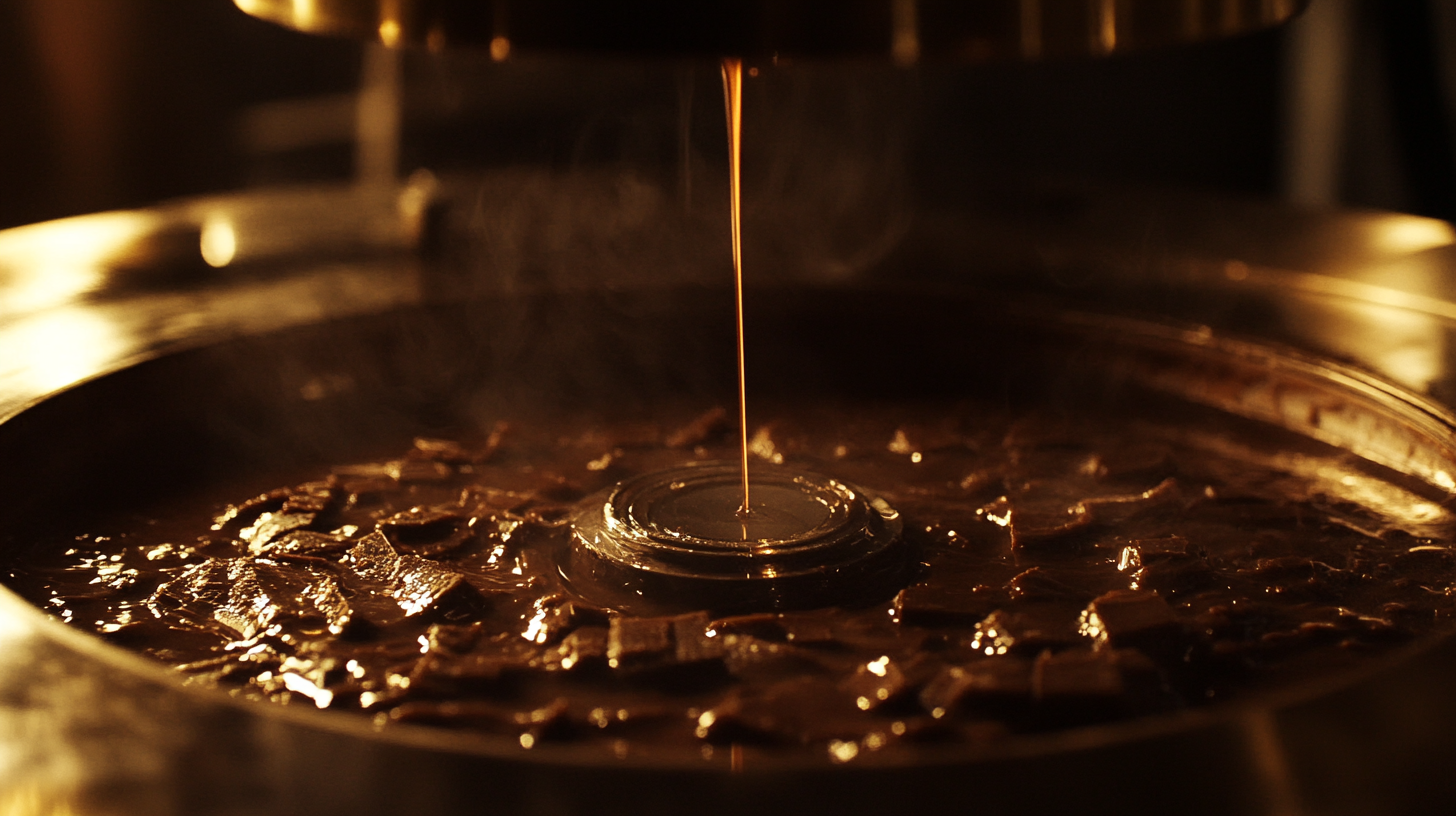

In the world of chocolate-making, achieving the perfect sheen and snap in your treats is a goal that many enthusiasts and professionals strive for. One essential tool that can help unlock these qualities is a tempering machine for chocolate. By ensuring the proper crystallization of cocoa butter, these machines streamline the tempering process, allowing chocolatiers to create confections that not only look stunning but also melt delightfully in the mouth. Whether you are a hobbyist looking to elevate your homemade chocolates or a professional seeking consistency and efficiency, understanding the role of a tempering machine is crucial.

As we delve into the intricacies of chocolate tempering, we'll explore how this indispensable device can transform your chocolate-making experience. From the science of crystallization to practical tips for getting the best results, we will uncover the secrets that will help you master the art of perfect chocolate. Join us on this journey, and discover how a tempering machine for chocolate can be the key to unlocking your creativity and achieving professional-grade results in your sweet creations.

Understanding the Role of Tempering in Chocolate Making

Tempering is a critical process in chocolate making that ensures the final product has a glossy finish, a firm snap, and a smooth texture. This technique involves carefully controlling the temperature of the chocolate to stabilize its cocoa butter crystals. According to a report by the Fine Chocolate Industry Association, properly tempered chocolate not only enhances visual appeal but also contributes to a more enjoyable eating experience, as the right crystal structure melts evenly at body temperature. When chocolate is improperly tempered, it may develop a dull appearance and a grainy texture. This often leads to chocolate seizing, resulting in unsightly bloom—white streaks caused by fat or sugar rising to the surface. Industry reports suggest that chocolate manufacturers can lose up to 30% of sales due to product defects linked to poor tempering processes. This emphasizes the necessity for using a tempering machine, which can precisely control heating and cooling cycles, ensuring the ideal conditions for crystallization. Furthermore, tempering machines have been shown to increase efficiency in production. A study by the National Confectioners Association indicates that chocolate makers using these machines can reduce tempering time by up to 50%, allowing for a quicker turnaround and enhancing overall productivity. As the chocolate industry continues to grow—projected to reach a market value of $172 billion by 2024—understanding the pivotal role of tempering is essential for any chocolatier aiming for quality and consistency in their products.

The Science Behind Chocolate Tempering: Why It Matters

Tempering chocolate is not merely an artisan's skill; it's a precise scientific process that ensures the perfect texture and shine that we associate with high-quality chocolate. This crucial step involves controlling the polymorphic states of cocoa butter, which is pivotal for chocolate’s structural integrity. Recent research highlights the importance of understanding cocoa butter's melting point, which is influenced by a specific gene that determines its properties. This discovery underscores the critical link between genetics and the quality attributes of chocolate, making it a topic of interest for chocolatiers and food scientists alike.

The process of tempering results in a desirable chocolate that melts smoothly in the mouth, a phenomenon that has been scientifically decoded by researchers. The mechanics of chocolate melting involve a carefully orchestrated release of fat and cocoa solids, enhancing flavor perception and texture. A study utilizing capacitance thermal analyzers has demonstrated variations in the melting properties of chocolate, indicating that fine-tuning the particle size during refining can significantly affect the final product’s melting behavior. This information is invaluable for chocolatiers aiming to enhance the sensory experience of their confections.

Innovations in chocolate production are also paving the way for healthier alternatives. By incorporating a small amount of saturated fat, the tempering process can be simplified, allowing for easier production without sacrificing quality. This not only streamlines the process but also opens avenues for creating guilt-free indulgences that maintain the luxurious texture and taste characteristic of high-end chocolates. As science and culinary arts converge, the future of chocolate looks not only delicious but also intriguing.

Selecting the Right Tempering Machine for Your Needs

When it comes to making perfect chocolate, selecting the right tempering machine is crucial. With various machines available on the market, knowing what features to look for can significantly enhance your chocolate-making experience. Consider the size of the machine; if you're working on a large scale, a commercial-grade tempering machine that can handle higher volumes is essential. However, for smaller batches, a compact home model can fulfill your needs without taking up too much space.

Temperature control is another key factor. A good tempering machine should allow for precise temperature adjustments, as maintaining the right temperatures is vital for achieving glossy, perfectly tempered chocolate. Look for models with digital displays and programmable settings that simplify the process. Additionally, pay attention to the machine’s capacity and heating time. Some machines may take longer to reach the desired temperature, potentially causing delays in your production.

Lastly, consider the ease of use and cleaning. Machines with user-friendly interfaces and removable parts will save you time and effort in maintenance. While browsing your options, read reviews or seek recommendations from fellow chocolatiers to find a machine that balances functionality with user satisfaction. Choosing the right tempering machine tailored to your needs will elevate your chocolate-making skills and ensure delicious, high-quality results every time.

Step-by-Step Guide to Using a Tempering Machine Effectively

When it comes to creating the perfect chocolate, tempering is non-negotiable. The tempering process ensures that chocolate maintains its sheen, snap, and smooth mouthfeel, which are all crucial features that consumers seek. A study from the Institute of Food Technologists indicates that properly tempered chocolate can increase shelf life by up to 40%, making the investment in a tempering machine a wise choice for professional confectioners and enthusiasts alike.

To use a tempering machine effectively, start by selecting high-quality chocolate with a cocoa content of at least 60%. This provides a rich flavor profile, with a smoother texture that enhances the overall chocolate experience. Next, follow a step-by-step procedure: begin with melting the chocolate to a temperature of around 45-50°C, ensuring that it is completely liquefied. When the chocolate reaches this state, gradually cool it down to about 27-28°C by adding small shavings of tempered chocolate or by using the machine's cooling feature.

After reaching the lower temperature, reheat the chocolate to between 31-32°C for dark chocolate and slightly lower for milk and white chocolates. At this point, it's essential to monitor the temperature precisely; deviations can lead to poor crystallization. An industry report from the American Confectioners Association reveals that about 70% of chocolate professionals emphasize the importance of temperature control in maintaining quality. By mastering these steps with your tempering machine, you'll unlock the secrets to producing chocolate that not only looks great but also delights the palate.

Common Mistakes to Avoid When Tempering Chocolate

When it comes to tempering chocolate, even the most experienced chocolatiers can fall prey to common mistakes that can ruin an otherwise perfect batch. One of the most frequent errors is not using a thermometer accurately. Chocolate must be heated and cooled to precise temperatures to achieve that glossy finish and satisfying snap. Overheating can lead to burnt chocolate, while underheating can prevent proper crystallization. Investing in a quality digital thermometer can help ensure that every step is executed flawlessly.

Another common pitfall is impatience during the cooling process. Tempering chocolate requires time and attention to detail; rushing can result in a less-than-ideal texture. When cooling, take your time and allow the chocolate to reach the desired temperature gradually. Stirring consistently during the cooling phase is essential, as it promotes even temperature distribution and can prevent clumps or graininess from forming.

Finally, using the wrong type or quality of chocolate can derail your tempering efforts. Always choose couverture chocolate, which contains a higher cocoa butter content, making it more suitable for tempering. Additionally, be sure to check the freshness of your chocolate; old or poorly stored chocolate can lead to inconsistent results. By being mindful of these common mistakes, you can unlock the secrets to achieving perfectly tempered chocolate every time.