Mastering the Art of Chocolate Conching with the Best Machines for Your Factory

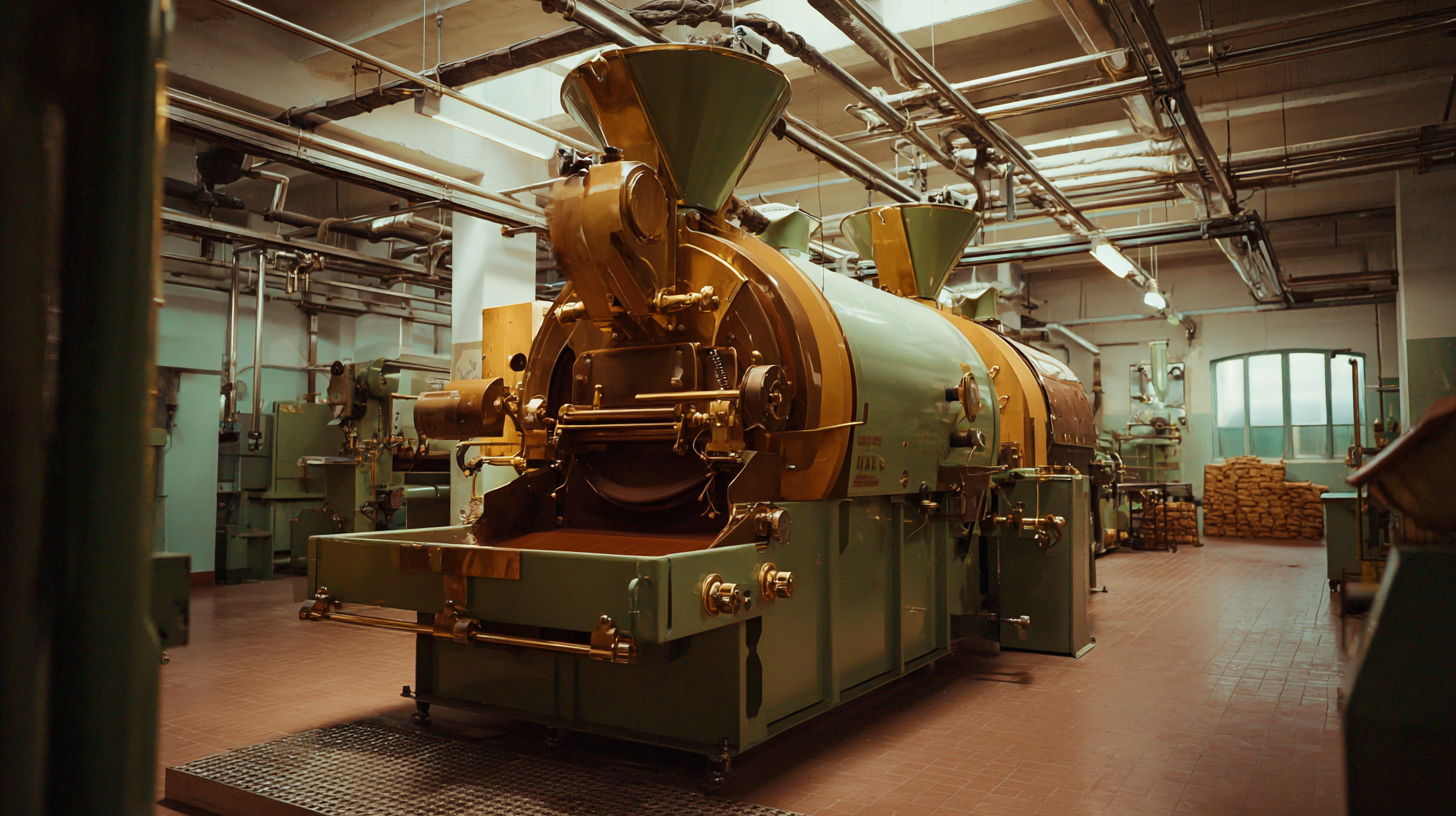

In the world of chocolate production, mastering the art of chocolate conching is essential for achieving the desired flavor and texture in finished products. According to the Chocolate Manufacturers Association, proper conching can enhance chocolate flavor by up to 30%, making the choice of equipment crucial for manufacturers. The market for chocolate conching machines has evolved significantly, with innovations leading to improved efficiency and consistency in production.

Various types of Chocolate Conching Machines cater to different product lines, from dark chocolate to milk and white varieties, each designed to optimize the specific characteristics of the chocolate. This blog will explore the unique features and applications of different conching machines, providing insights to help factory owners and chocolatiers select the best equipment for their operations, ensuring they can produce the highest quality chocolate possible.

Understanding the Conching Process: The Heart of Chocolate Production

The conching process plays a pivotal role in chocolate production, transforming raw chocolate into a smooth, rich product. According to a report by the International Cocoa Organization, the conching stage can affect up to 25% of the overall flavor development in chocolate. During this phase, chocolate liquor is continuously mixed and aerated, allowing volatile acids and moisture to escape. This not only enhances the flavor profile but also improves the texture, making it less gritty and more palatable.

In addition to flavor enhancement, conching is crucial for achieving the desired viscosity and mouthfeel. A study highlighted in the Journal of Food Science revealed that well-conched chocolate could reduce fat content while maintaining creaminess, a vital factor for manufacturers aiming to create premium products. The best chocolate conching machines utilize advanced technology to monitor temperature and time, optimizing these variables to ensure a consistent output. With manufacturers increasingly focused on quality, investing in high-performance conching equipment is essential for any factory looking to excel in the chocolate industry.

Essential Features to Look for in Chocolate Conching Machines

When it comes to chocolate manufacturing, conching is a critical process that significantly influences the flavor and texture of the final product. To ensure optimal results, selecting the right chocolate conching machine is paramount. One of the essential features to look for is the machine’s ability to achieve consistent temperature control. Studies show that maintaining a temperature around 50-60°C during conching can enhance the flavor profile and reduce bitterness. An ideal machine should also facilitate adjustable mixing speeds, allowing manufacturers to fine-tune their processes for different chocolate types.

Another important feature is the machine's capacity and efficiency. According to market analysis reports, chocolate confectionery production has surged by 4.5% annually, indicating a growing need for high-capacity machines that can keep up with demand. It’s advisable to invest in machines that offer a batch size suitable for your production needs while maintaining energy efficiency. Many modern machines now come equipped with smart technology that allows for real-time monitoring of the conching process, which can lead to significant improvements in product consistency and quality.

Tip: Always consider machines that provide easy maintenance access, as regular upkeep can significantly extend the lifespan of your equipment. Additionally, opting for machines with built-in sensors can help you quickly identify and rectify any inconsistencies during production, ensuring high-quality outcomes with every batch.

Top Brands for High-Performance Chocolate Conching Equipment

When it comes to chocolate manufacturing, having the right equipment is crucial for achieving optimal results in conching and refining processes. The top brands in high-performance chocolate conching equipment are committed to meeting the demands of modern chocolate production. They offer advanced cocoa grinders and melanger machines equipped with features like speed controllers that allow manufacturers to tailor the refining process to their specific needs. As the market becomes increasingly competitive, investing in high-quality machines can significantly enhance production efficiency and reduce operational costs.

In addition to performance, sustainability is becoming a key focus in chocolate processing. Many manufacturers are now integrating liquid-cooled motors into their systems, which not only improves energy efficiency but also supports environmental goals. This shift towards more sustainable practices is essential for meeting the growing consumer demand for environmentally friendly products. By utilizing innovative processing technologies and sustainable machinery, chocolate producers can enhance their product quality while also aligning with the latest industry trends towards responsible production.

| Machine Type | Capacity (kg/hour) | Power (kW) | Material | Price Range (USD) |

|---|---|---|---|---|

| Batch Conching Machine | 50 | 15 | Stainless Steel | 10,000 - 15,000 |

| Continuous Conching Machine | 100 | 30 | Aluminum | 20,000 - 25,000 |

| Universal Conching Machine | 75 | 22 | Steel | 15,000 - 20,000 |

| Vacuum Conching Machine | 60 | 25 | Copper | 18,000 - 23,000 |

| Small Scale Conching Machine | 30 | 10 | Plastic | 5,000 - 8,000 |

Optimizing Your Factory's Efficiency with Advanced Conching Techniques

When it comes to chocolate production, optimizing your factory’s efficiency is crucial, and advanced conching techniques play a pivotal role in achieving this goal. Conching is the process that refines chocolate, resulting in the smooth texture and rich flavors that consumers love. Investing in state-of-the-art conching machines can significantly reduce production time while enhancing the overall quality of the chocolate. These machines are designed to provide consistent heat and agitation, allowing for a more thorough and efficient conching process.

Moreover, integrating automation into your conching operations can lead to smarter factory workflows. Automated machines can monitor and adjust parameters in real-time, ensuring that the chocolate achieves the desired viscosity and flavor profile without constant human intervention. This not only boosts productivity but also minimizes waste by optimizing ingredient usage throughout the conching process. By embracing these advanced techniques and machinery, manufacturers can not only streamline their operations but also elevate their chocolate products to new heights of excellence.

Common Challenges in Chocolate Conching and How to Overcome Them

Chocolate conching is a critical step in chocolate production, yet it poses several challenges for manufacturers. One common issue is achieving the right particle size and texture. According to a report by the Fine Chocolate Industry Association, nearly 85% of chocolate makers report that inconsistent conching techniques lead to subpar mouthfeel and flavor release, impacting the overall quality of the product. To address this, investing in advanced conching machines with precise temperature control and adjustable mixing speeds can significantly enhance the uniformity of the chocolate mass.

Another significant challenge is the efficient removal of volatile acids to improve flavor profiles. Data from the International Journal of Food Science indicated that improper conching times could result in a flavor loss of up to 30%, affecting consumer satisfaction. To counter this issue, manufacturers should implement automated monitoring systems that track acidity levels in real-time, allowing for timely adjustments during the conching process. By overcoming these challenges through technology and diligent monitoring, factories can elevate their chocolate quality, satisfying both artisanal and mass-market demands.