Understanding Global Industry Standards for the Best Chocolate Cutting Machine: A Purchasing Guide

The global chocolate market is poised for substantial growth, projected to reach a value of nearly $160 billion by 2025, driven by rising consumer demand for chocolate products and innovations within the industry. As manufacturers seek to enhance efficiency and quality in production, the significance of specialized equipment, such as the Chocolate Cutting Machine, cannot be overstated.

These machines play a crucial role in maintaining consistency and precision in chocolate cutting processes, which are essential for meeting industry standards and consumer expectations. According to recent market analysis, advancements in technology and the increasing focus on automation are influencing the development of cutting machines, making it imperative for businesses to understand global industry standards when investing in this essential machinery.

This guide will provide insights into selecting the best Chocolate Cutting Machine to facilitate growth and ensure compliance with market demands.

These machines play a crucial role in maintaining consistency and precision in chocolate cutting processes, which are essential for meeting industry standards and consumer expectations. According to recent market analysis, advancements in technology and the increasing focus on automation are influencing the development of cutting machines, making it imperative for businesses to understand global industry standards when investing in this essential machinery.

This guide will provide insights into selecting the best Chocolate Cutting Machine to facilitate growth and ensure compliance with market demands.

Key Features to Look for in a Quality Chocolate Cutting Machine

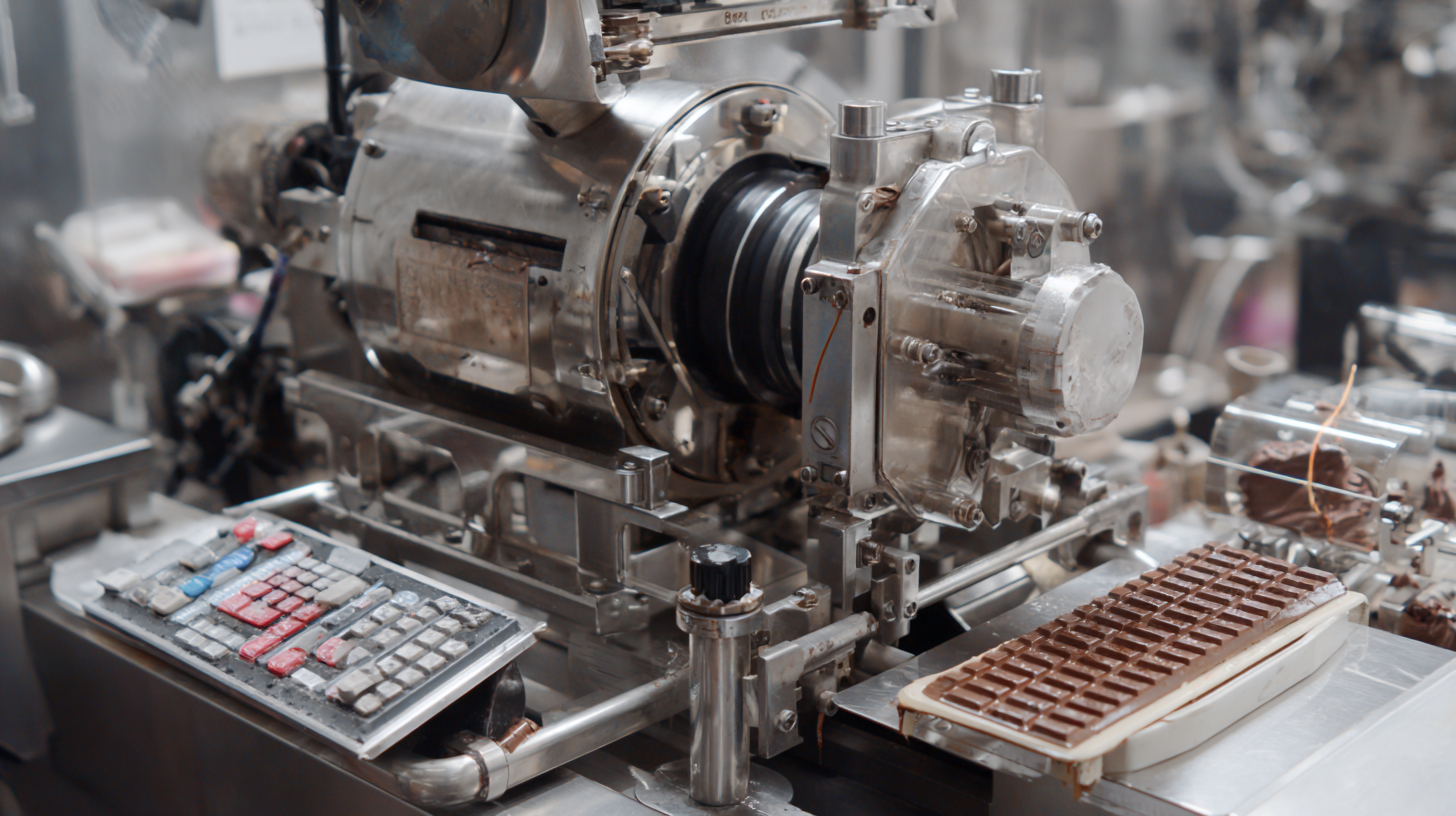

When searching for the best chocolate cutting machine, it’s essential to consider several key features that guarantee efficiency and precision. First and foremost, the cutting mechanism should be robust yet versatile, capable of handling various chocolate types and shapes. Machines equipped with adjustable blades allow for different thicknesses, providing flexibility for various chocolate products, from bars to intricate designs. This adaptability is particularly crucial for businesses that require a range of chocolate forms to meet customer demand.

Another significant aspect to evaluate is the machine's safety and ease of use. A quality chocolate cutting machine should come with safety features such as blade guards and emergency stops to protect operators during use. Additionally, user-friendly controls and intuitive interfaces can significantly enhance productivity, minimizing downtime and training requirements.

Lastly, consider the machine’s maintenance needs. Selecting a model designed with easy maintenance in mind can prolong its lifespan and ensure consistent performance, making your chocolate cutting operations smoother and more efficient.

Understanding Chocolate Industry Standards and Compliance Regulations

In the chocolate manufacturing industry, adherence to global standards and compliance regulations is crucial for ensuring product quality and safety. The International Organization for Standardization (ISO) has set forth guidelines that chocolate producers must follow, notably ISO 22000, which addresses food safety management systems. According to a report by Research and Markets, the global chocolate market is projected to reach $161 billion by 2024, emphasizing the need for manufacturers to comply with stringent regulations to maintain competitiveness.

Furthermore, the FDA has specific guidelines for the labeling and composition of chocolate products, which are vital for consumer trust and market acceptance. Non-compliance can lead to hefty penalties and damage a brand’s reputation. The Cocoa Standards are also essential; for example, compliant chocolate must contain a minimum cocoa liquor percentage, depending on the product type. By adhering to these industry standards, businesses not only reassure consumers but also enhance their operational efficiencies, ultimately impacting their bottom line positively. As a result, investing in the best chocolate cutting machines that meet these regulations is not only a matter of compliance but also a strategic decision for quality production.

Comparing Different Types of Chocolate Cutting Machines and Their Applications

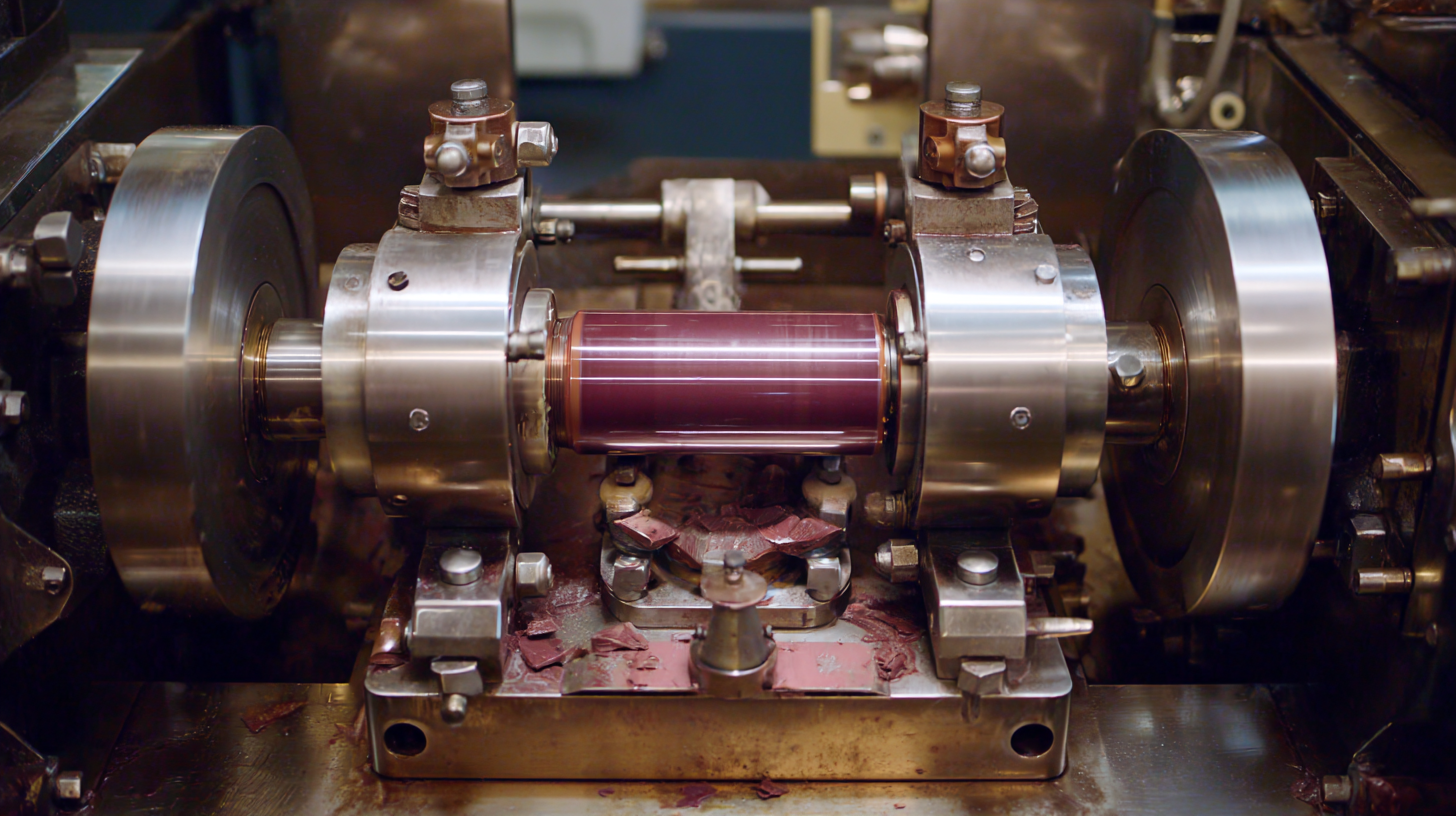

When it comes to chocolate production, selecting the right chocolate cutting machine is crucial for achieving the desired texture and presentation of your confections. There are various types of cutting machines available, each designed for specific applications within the chocolate-making process. For instance, a band saw machine offers precision cutting for large chocolate blocks, making it ideal for manufacturers who produce artisanal bars or large figures. Its ability to maintain a clean cut minimizes waste and ensures uniformity in product size.

On the other hand, there are rotary cutting machines that employ circular blades to slice chocolate with speed and efficiency. These machines are particularly beneficial for high-volume operations, such as those producing chocolate-coated treats or bite-sized candies. Their quick processing time allows for a seamless transition from production to packaging, maintaining the quality of the chocolate while optimizing workflow. Understanding these differences is essential for manufacturers aiming to enhance production quality and adapt to varying market demands.

Cost Considerations: Finding the Best Value for Your Chocolate Cutting Machine

When considering the purchase of a chocolate cutting machine, cost is often a primary concern for manufacturers looking to balance quality with budget.

According to a recent report from IBISWorld, the manufacturing of chocolate products generates over $24 billion in revenue in the U.S. alone, indicating the significant investment companies make in their production equipment.

A chocolate cutting machine can range anywhere from $3,000 to over $30,000 based on its features, capacity, and technology.

Therefore, understanding the value derived from different price points is essential for making a sound investment.

Moreover, operators should consider the long-term savings associated with higher-quality machines, which often boast advanced cutting technology that reduces waste and improves consistency.

The global chocolate market is anticipated to grow at a CAGR of 4.5% from 2021 to 2026, emphasizing the need for efficient production methods.

Investing in a reliable machine may lead to lower operating costs and increased profitability, making it a vital consideration for any chocolate producer aiming to optimize their output while maintaining competitive pricing.

Tips for Maintenance and Longevity of Your Chocolate Cutting Equipment

When investing in a chocolate cutting machine, maintenance is key to ensuring its longevity and optimal performance. Regular cleaning is essential; residue from chocolate can accumulate over time, affecting the quality of your product and the machinery itself. Use a mild cleanser and soft cloth to wipe down the surfaces after each use, and make sure to thoroughly clean the cutting blades to avoid any buildup that could hinder their effectiveness.

Another important tip for the maintenance of your chocolate cutting equipment is to perform regular inspections and servicing. Check for any wear and tear on the parts, particularly the blades and motors. Lubricate moving components as per the manufacturer's guidelines to prevent friction and overheating. Keeping a consistent maintenance schedule can help you identify potential issues early, thus extending the life of your machine and ensuring consistent cutting precision.

Lastly, always refer to the manufacturer’s manual for specific care instructions tailored to your model. Following these guidelines not only enhances the machine’s performance but also minimizes the need for costly repairs, ensuring that your chocolate production runs smoothly for years to come.