Why Chocolate Machine Tempering is Essential for Perfect Chocolate Treats

In the world of chocolate making, the process of achieving the perfect texture and shine is crucial for crafting delectable chocolate treats. One of the key techniques that chocolatiers employ is Chocolate Machine Tempering. This method not only ensures that chocolate reaches its optimal state but also enhances its flavor and shelf-life. Proper tempering involves carefully controlling the temperature of chocolate to stabilize the cocoa butter crystals, allowing the chocolate to harden evenly and produce a glossy finish.

Chocolate Machine Tempering offers several advantages over traditional tempering methods. It provides consistent results due to precise temperature controls and reduces the risk of errors, making it an ideal choice for both professional chocolatiers and home bakers. By employing this technology, chocolate makers can streamline their processes while achieving superior results. As we delve deeper into the importance of Chocolate Machine Tempering, we will explore the science behind tempering chocolate and how mastering this technique elevates the quality of chocolate confections.

Definition of Chocolate Tempering and Its Importance

Chocolate tempering is a crucial process that involves carefully heating and cooling chocolate to stabilize its structure. This technique ensures that the cocoa butter crystals within the chocolate form a uniform and stable crystalline structure, which is essential for achieving a glossy finish and a satisfying snap when the chocolate is broken. Properly tempered chocolate not only looks appealing but also melts beautifully in the mouth, enhancing the overall sensory experience of chocolate treats.

The importance of chocolate tempering cannot be overstated, especially for chocolatiers and pastry chefs. When chocolate is tempered correctly, it reduces the likelihood of fat bloom—a grayish-white coating that occurs when the chocolate has not been stabilized, negatively affecting its appearance and texture. Additionally, tempered chocolate is more resistant to melting at room temperature, making it ideal for creating delicate confections that maintain their quality during handling and display. Overall, mastering the art of chocolate tempering is essential for anyone looking to create perfect chocolate treats that delight both the eyes and the palate.

The Science Behind Chocolate Tempering Process

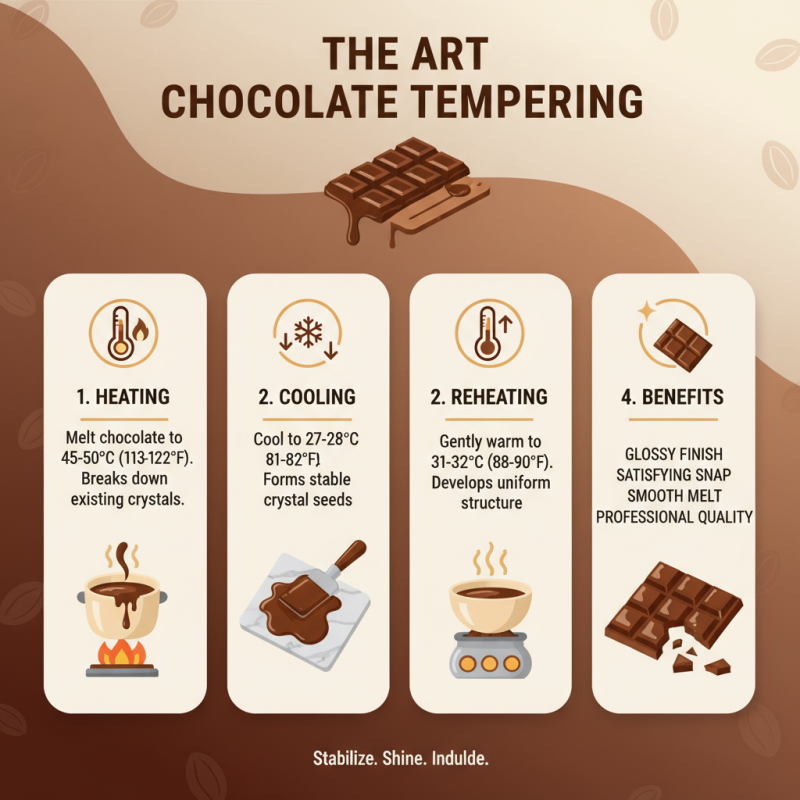

The tempering of chocolate is a crucial step in the chocolate-making process, ensuring that the final product has the right texture, shine, and snap. When chocolate is tempered correctly, it undergoes a sequence of heating and cooling that aligns the cocoa butter crystals, resulting in a stable crystalline structure. According to the Fine Chocolate Industry Association, properly tempered chocolate has a significant impact on both the aesthetic appeal and mouthfeel of the treat, while also enhancing its shelf life.

From a scientific perspective, the tempering process typically includes heating the chocolate to around 45-50°C (113-122°F), cooling it down to about 27°C (80°F), and then reheating it slightly to around 31-32°C (88-90°F) for dark chocolate. This precise control of temperature encourages the formation of beta crystals, the most stable type of cocoa butter crystals that give the chocolate its glossy finish and firm texture. Research has shown that improperly tempered chocolate not only lacks the desired sheen but may also develop a dull, grayish bloom due to fat migration, which can negatively affect consumer perception and product quality.

Moreover, a report from the International Journal of Food Science and Technology highlights that tempering chocolate can enhance its snap, a critical quality indicator for chocolate lovers. It was found that chocolate with well-tempered cocoa butter crystals has a higher breaking point and a smoother melt, providing a more enjoyable eating experience. Therefore, understanding and implementing the science behind chocolate tempering is essential for chocolatiers who aim to produce high-quality chocolate treats that meet both aesthetic and sensory standards.

Why Chocolate Machine Tempering is Essential for Perfect Chocolate Treats - The Science Behind Chocolate Tempering Process

| Tempering Stage | Temperature (°C) | Time Duration | Purpose |

|---|---|---|---|

| Melting | 45-50 | 5-10 minutes | Melt cocoa butter and mass |

| Cooling | 27-29 | 10-15 minutes | Form stable crystals |

| Reheating | 30-32 | 5 minutes | Stabilize the chocolate for molding |

| Molding | Room Temperature | Varies | Allow chocolate to set |

Step-by-Step Guide to Proper Chocolate Tempering Techniques

Tempering chocolate is a crucial step for achieving glossy, smooth, and snap-worthy treats. Proper chocolate tempering involves carefully melting chocolate and then cooling it to stabilizing the cocoa butter crystals within. This process not only enhances the appearance of your chocolate but also improves its texture and shelf life. Follow these step-by-step techniques to temper chocolate perfectly.

Begin by chopping your chocolate into small, uniform pieces to ensure even melting. Use a double boiler or a microwave to melt about two-thirds of your chocolate until it reaches around 110°F (43°C). Once melted, remove it from heat and stir in the remaining one-third of the chopped chocolate to cool it down. Continue stirring until the temperature drops to about 88°F to 90°F (31°C to 32°C). This method, known as the seeding technique, helps to introduce stable cocoa butter crystals and promotes a smooth finish.

Tips: Always ensure your tools and surfaces are completely dry and clean, as even a tiny amount of moisture can cause chocolate to seize. If you're working with colored cocoa butter or various flavorings, make sure they are compatible with your chocolate and avoid introducing too much liquid. Lastly, if the chocolate becomes too thick during tempering, gently reheat it in short intervals, ensuring you don't exceed the necessary temperature.

Common Mistakes When Tempering Chocolate and How to Avoid Them

Tempering chocolate is a crucial process that can significantly impact the quality of your chocolate treats. However, it is easy to make mistakes if you're not aware of common pitfalls. One frequent error is not reaching the proper temperature during the melting phase. When chocolate is heated too high, it can lose its tempering properties, resulting in a dull finish and a lack of snap. To avoid this, it’s essential to use a thermometer to monitor the temperature closely, ensuring it falls within the ideal range for the type of chocolate you are using.

Another common mistake is not stirring the chocolate adequately while tempering. Inadequate stirring can lead to uneven temperature distribution, which might result in parts of the chocolate being over-tempered or under-tempered. To prevent this, always stir consistently and thoroughly during the process. Additionally, ensuring that all utensils and surfaces are clean and dry will help prevent unwanted moisture from introducing graininess, which can compromise the texture and appearance of your finished products. By being mindful of these issues, you can achieve smooth, glossy, and perfectly tempered chocolate every time.

Impact of Tempering on Texture and Appearance of Chocolate Treats

Tempering chocolate is a critical step in the confectionery process that significantly influences both the texture and appearance of chocolate treats. During tempering, chocolate is carefully heated and cooled to stabilize the cocoa butter crystals, promoting the formation of a consistent crystalline structure. This process is vital because it results in chocolate that has a smooth, glossy finish and a satisfying snap when broken. When chocolate is not tempered correctly, it can become dull, uneven, and have a gritty texture, which detracts from the overall quality of the treats.

The impact of proper tempering extends beyond aesthetics; it also affects mouthfeel and melting properties. Well-tempered chocolate melts perfectly in the mouth, providing a pleasurable experience. Conversely, improperly tempered chocolate can have a waxy mouthfeel and may not melt evenly, leading to a subpar eating experience. Additionally, the stability achieved through tempering ensures that the finished products resist bloom—a white film that can develop from fat migration. By maintaining the integrity of the chocolate's appearance and texture, tempering becomes essential for creating high-quality chocolate treats that not only look appealing but also deliver exceptional taste.

Impact of Chocolate Tempering on Texture and Appearance

Related Posts

-

7 Secrets to Choosing the Best Tempering Machine for Chocolate

-

Global Market Trends for Chocolate Machine Tempering by 2025 and How to Choose the Right Equipment

-

Chocolate Production Insights for Global Buyers Seeking Innovative Tempering Solutions

-

Challenges Faced by Buyers of Tempering Machines for Chocolate

-

Future Innovations in Industrial Chocolate Tempering Machines by 2025

-

Ultimate Comparison: Top Tempering Machines for Chocolate - Find the Perfect Fit for Your Production Needs