Best Welded Wire Mesh Options for Your Projects?

welded wire mesh is an essential material for various construction and fencing projects. It provides strength and durability, making it a preferred choice among builders. John Smith, a noted expert in the welded wire mesh industry, once stated, "Choosing the right welded wire mesh can make or break your project's success." This highlights the importance of making informed selections.

Many options are available in the welded wire mesh market. However, not every product fits all needs. It's crucial to consider the specific application, whether for a garden fence or an industrial project. The right choice can enhance the structural integrity of your work.

Yet, some may overlook the quality differences in welded wire mesh products. Poor choices can lead to costly repairs and time lost. Reflecting on your needs and project requirements is vital. High-quality welded wire mesh can significantly impact the project's overall performance and longevity.

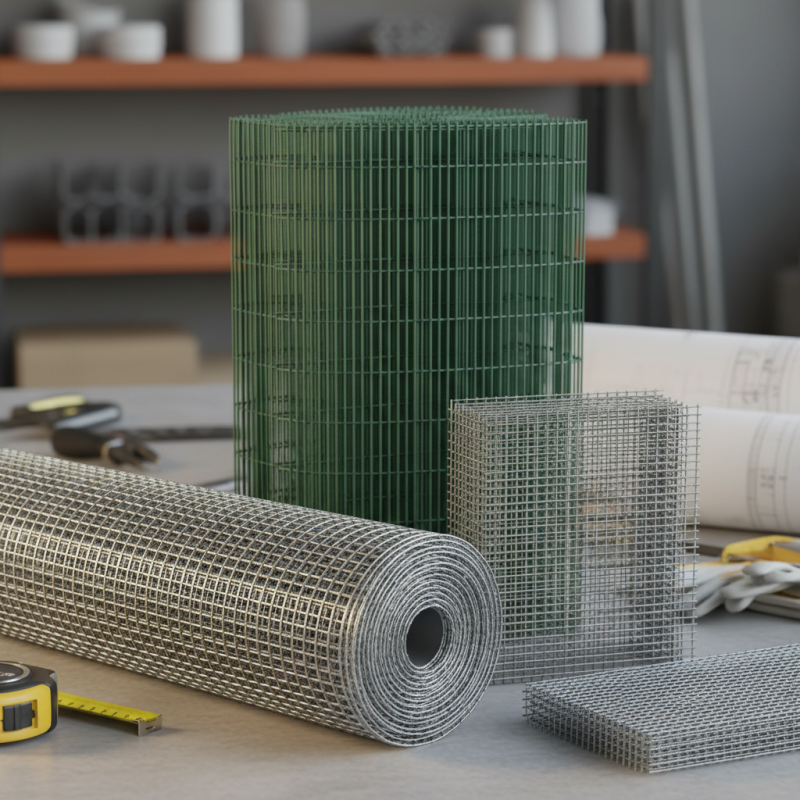

Types of Welded Wire Mesh Available for Various Applications

Welded wire mesh is versatile for various projects. Its applications range from fencing to reinforcing concrete. Understanding the types available is crucial for selecting the right option.

Common types include standard welded wire mesh, which is often used in construction and landscaping. It comes in different sizes and gauges to suit various needs. For livestock, heavy-duty welded wire mesh provides security and durability. This type can withstand harsh environments. Consider using smaller mesh for garden projects to keep out pests.

Tips: Always measure your project area accurately. This helps in choosing the correct size of mesh. When buying, ensure the wire gauge meets your strength requirements. If unsure, consult with a professional.

Another type is galvanized welded wire mesh. It's resistant to rust and corrosion, making it ideal for outdoor use. This option is beneficial for long-term projects exposed to moisture. For arts and crafts, use decorative welded wire mesh. It adds a unique touch to handmade items.

Tips: Check for sharp edges on the mesh before installation. These can cause injury. Always wear gloves when handling wire mesh to prevent cuts. Pay attention to the spacing of the welds; uneven spaces may reduce the mesh's overall effectiveness.

Factors to Consider When Choosing Welded Wire Mesh

When choosing welded wire mesh, several factors come into play. The gauge of the wire significantly impacts strength and application. Thicker wires tend to provide more durability, while thinner options may be suitable for less demanding tasks. Consider the spacing between the wires as well. Tighter spacing enhances security but may restrict airflow.

Tips: Always check the wire gauge before purchasing. Thicker wires offer better support for barriers and fencing. However, if you need flexibility, lighter options can be easier to work with.

The type of coating can also influence your decision. Galvanized coatings resist rust and corrosion, making them ideal for outdoor use. Powder-coated options provide aesthetic appeal but may have limitations in harsh conditions. Evaluate your project needs before committing to one type.

Tips: If your project is outdoors, prioritize galvanized wire. Don’t overlook the importance of proper installation, as a poorly installed mesh can lead to failures later. Stay mindful of your surroundings and environmental effects on the mesh over time.

Comparison of Material Options for Welded Wire Mesh

When selecting welded wire mesh for your projects, consider the material options available. Galvanized steel is a popular choice. It offers strong corrosion resistance. This makes it ideal for outdoor settings. However, its weight can be a downside for some applications. Lighter options include stainless steel. While it is expensive, it provides excellent durability. Additionally, its sleek appearance is a plus for decorative uses.

Plastic welded wire mesh can be a viable alternative. It is lightweight and resistant to rust. Many people appreciate its versatility. However, it may not hold up under heavy loads. Think carefully about your project's requirements. If your goal is long-term durability, plastic might not suffice. On the other hand, reinforced wire mesh provides added strength. This is critical for heavy-duty applications. Keep in mind that heavier materials can be challenging to work with.

Ultimately, the decision hinges on specific project needs. You may find yourself unsure about which option to choose. Testing different materials may yield surprising insights. Don’t overlook the importance of cost versus functionality. Balancing these factors can elevate your project outcomes significantly.

Installation Techniques for Welded Wire Mesh Projects

When working with welded wire mesh, proper installation techniques are crucial. Begin by preparing the area well. Clear away debris and level the ground. This step might seem tedious, but it sets the foundation for success. If the ground is uneven, the mesh may not sit properly.

Next, cut the mesh to fit the project dimensions. Use appropriate tools to avoid sharp edges that could cause injuries. If the mesh doesn’t lay flat, bending or adjusting might be necessary. Remember, a small mistake can lead to larger issues in your project. Secure the mesh with stakes or fasteners. It’s helpful to frequently check alignment. Misalignment can compromise the integrity of the structure.

After installation, consider reinforcing the edges. This adds durability and helps prevent rust or wear over time. You might find that some sections pull away; it’s not unusual. Regular maintenance checks ensure the mesh remains in good condition. Planning for these potential problems can save you time and effort later on.

Best Welded Wire Mesh Options for Your Projects

| Mesh Size (inches) | Wire Gauge | Material | Coating Type | Best Use Case |

|---|---|---|---|---|

| 1 x 1 | 16 | Galvanized Steel | Electro-Galvanized | Animal Enclosures |

| 2 x 2 | 14 | Stainless Steel | PVC Coated | Security Fencing |

| 3 x 3 | 12 | Carbon Steel | Hot-Dipped Galvanized | Construction Reinforcement |

| 4 x 4 | 10 | Aluminum | None | Garden Fencing |

| 6 x 6 | 8 | Fiberglass | UV Resistant | Industrial Applications |

Common Uses and Benefits of Welded Wire Mesh in Construction

Welded wire mesh is a versatile material widely used in construction. Its structure consists of intersecting wires welded at the junctions, providing strength and durability. This makes it an excellent choice for reinforcing concrete slabs, walls, and even driveways. It offers consistent support, preventing cracks and ensuring longevity in various applications.

Common uses of welded wire mesh include fencing, animal enclosures, and garden trellises. The mesh can keep unwanted animals out while allowing sunlight and air circulation. However, it’s essential to select the right gauge and spacing for the specific project. Some might find that thinner options bend easily or do not provide sufficient security. Regular maintenance can also be a challenge. Over time, rust can develop, impacting both durability and aesthetics.

One common benefit of welded wire mesh is its cost-effectiveness. It typically requires less labor due to its easy installation. Yet, improper handling can lead to bending or damage. It’s crucial to plan ahead and measure accurately. Overall, welded wire mesh provides many advantages, but like any material, it has its limitations. Understanding these factors helps in making informed decisions for construction projects.

Best Welded Wire Mesh Options for Your Projects

Welded wire mesh is a versatile construction material, widely used in various projects. This chart illustrates the common applications, showcasing the percentage of use in different sectors, revealing its importance in construction, agriculture, fencing, and more.