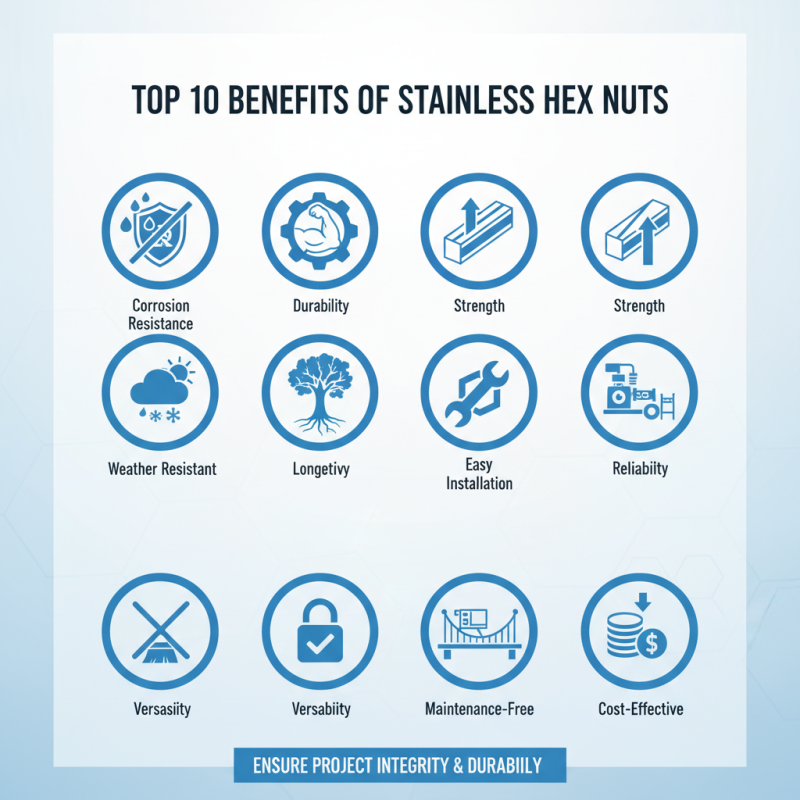

Top 10 Benefits of Stainless Hex Nuts for Your Projects?

In the world of construction and manufacturing, the importance of Stainless Hex Nuts cannot be understated. According to industry expert John Smith, "Stainless Hex Nuts are crucial for ensuring project integrity and durability." These small but mighty fasteners play a vital role in various applications, from machinery to furniture assembly.

Stainless Hex Nuts stand out due to their resistance to corrosion. This feature makes them perfect for outdoor use. They maintain strength even in harsh conditions, providing reliability that is hard to match. Their design allows for easy handling and installation, which can save considerable time on projects. However, not all Stainless Hex Nuts are equal; quality varies, and subpar options can lead to failures.

Understanding the benefits of Stainless Hex Nuts can greatly enhance project outcomes. Attention to detail in fastener selection is critical. It’s easy to overlook these components, yet their impact is significant. Projects can suffer if the wrong materials are used. Being mindful of these details ensures that the constructed elements fulfill their intended purpose efficiently.

Understanding Stainless Hex Nuts: An Overview of Their Composition

Stainless hex nuts are essential components in many projects. These nuts are made from a mix of iron, chromium, and nickel. This combination provides excellent corrosion resistance. It's not just about strength; their composition ensures longevity. Some users may overlook the quality of the materials used. The choice of stainless steel can make or break the project's durability.

The design of hex nuts allows for easy installation. This shape supports a secure grip, enhancing safety in assembly. Small imperfections in manufacturing could affect these benefits. A poor fit can result in project failures. It's crucial to inspect nuts before use. Pay attention to the surface finish and threading. Each detail matters in ensuring a successful outcome. These factors contribute to the overall effectiveness of your projects.

Corrosion Resistance: Why Stainless Hex Nuts Are Ideal for Harsh Environments

Stainless hex nuts offer remarkable corrosion resistance, making them the preferred choice for challenging environments. These nuts are crafted from stainless steel, which is known for its ability to withstand moisture and chemicals. In settings like marine or industrial locations, stainless hex nuts show resilience against rust and degradation. This durability ensures that they maintain their strength over time, even with exposure to harsh conditions.

Quality matters. Using high-grade stainless hex nuts can prevent unexpected failures. Always check if the nut meets industry standards. For best results, ensure the threads match your bolts perfectly. Misfits can cause problems. It’s also important to apply lubrication to reduce friction. This can enhance the joint's integrity, providing extra security against loosening.

Tip: Store stainless hex nuts properly, away from wet conditions. This simple step can prolong their life. Regular inspections can reveal wear or corrosion early. Be mindful of the environment where these nuts will be used. Extreme temperatures may affect their performance, too. Adapt your choice to the project’s demands for best results.

Strength and Durability: The Structural Benefits of Stainless Hex Nuts

Stainless hex nuts are essential in construction and mechanical projects. Their strength and durability set them apart from standard options. They can withstand extreme conditions. Corrosion resistance is a key feature. This makes them ideal for outdoor applications. In marine environments, for example, these nuts outperform their counterparts.

Using stainless hex nuts can enhance structural integrity. They provide reliable fastening solutions, minimizing the risk of failure. Their solid construction can bear heavy loads. However, not all projects may need stainless steel. Consider cost and application before choosing. Sometimes, a simpler option might suffice. Each project has unique demands which may lead to overspending.

While the benefits are clear, it’s essential to reflect on obstacles too. Incorrect installation can lead to issues. Aligning threads properly is crucial for performance. Time spent on proper fitting can save future headaches. Balancing quality and budget is an ongoing challenge for many. In the end, the choice of fastening hardware should match the project's specific needs.

Versatility in Applications: Using Stainless Hex Nuts in Various Projects

Stainless hex nuts are incredible for various projects. Their versatility makes them a go-to option in many industries. From construction to automotive, their applications are numerous. The durability of stainless steel ensures they resist rust and corrosion. This is vital for outdoor projects or humid environments.

Using stainless hex nuts in your work can enhance structural integrity. They lock tightly, preventing loosening under vibration. This is especially important in machinery and vehicles. However, selecting the right size and thread type can be tricky. Misalignment can lead to weaker connections. Always double-check specifications before starting your project.

Another intriguing aspect is their aesthetic appeal. Stainless hex nuts can be used in decorative applications, too. They add an industrial touch to furniture or art projects. However, be mindful of overusing them; less can be more in design. With careful thought, these nuts can create stunning visual elements. Consider both function and form for the best results.

Cost-Effectiveness: Analyzing Long-Term Savings with Stainless Hex Nuts

Stainless hex nuts offer significant cost-effectiveness for various projects. A recent industry report indicates that using stainless steel fasteners can reduce long-term expenses by up to 30%. These savings mainly stem from their durability and resistance to corrosion. They last longer in harsh environments compared to carbon steel options, which often require frequent replacements.

Additionally, stainless hex nuts can lower maintenance costs. In many applications, high-quality stainless nuts do not need regular lubrication. This is key for projects in demanding settings, such as marine or chemical plants. An interesting fact from industry studies shows that maintenance teams can spend around 10-15% of their budgets on repairing and replacing corroded fasteners. Using stainless nuts greatly reduces this expenditure.

However, there are considerations to be made. The initial cost of stainless hex nuts is higher than other materials. Many projects might feel the pinch upfront. It's crucial to evaluate your specific needs and budget. Despite this, the overall savings are compelling. The trade-off between initial investment and long-term benefits is worth analyzing closely.